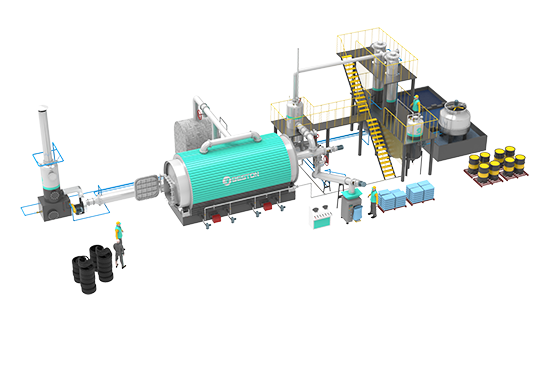

Pyrolysis is a process which involves molecular breakdown whereby large molecules break down into much smaller molecules. Pyrolysis plants is an industry that carries out the pyrolysis of waste tires and plastic, whereby waste products are broken down and separated into different end products. In regard to tires and plastic pyrolysis, the long-chain polymers break down into small chains of pyrolysis oil and hydrocarbon gas. A catalyst and heat is a requirement for these reactions.

Here is a list of the end products from the process of tire pyrolysis:

1. Fuel Oil

The primary oil product that is produced by these recycling applications (venta de la planta de pirólisis) is known as fuel oil. This product is used widely for commercial and industrial purposes all over the world. The oil produced from recycled waste or scrap tires usually accounts for 40 to 45% of the end product produced and is typically carried away by tanker trucks.

2. Carbon Black

Carbon black is another product that is recycled through pyrolysis technology (planta reciclaje de neumaticos). The carbon black that is recycled usually makes up 30 to 35% of the end product produced, which will depend on the tire types used. Carbon black is then used as the main ingredient or raw materials in a number of different industries. The chemical make-up of carbon black lengthens and strengthens the overall endurance of certain products, along with improving the color features in association with specific materials.

Carbon black which is produced through pyrolysis application is a lot more economical when compared to carbon black which is produced mainly from petroleum and it is also far more cost-effective. Carbon black is frequently used in these industries:

- Rubber additives

- Electric cable jacketing

- Black colorant for rubber materials

- Conveyor belts

- Doormats

- Heat isolation

- Black nylon bags

- Carrier bands

- Industrial rubber products

- Plastic pipes

3. Steel Wire

Tires all contain steel wires which amount to around 15 to 20% of the overall tire weight. The steel that is present in these tires is detached through the recycling process of pyrolysis (bestongroup)

. This valuable end product is then compressed and later sold to scrap and steel dealers.

4. Gas

The gas produced through the pyrolysis process of waste tires makes up between 5 to 7% of the end products. The non-condensable gases produced through these recycling applications are associated with the following features:

- The recycled gas has a calorific value (Valor calorífico) which is higher in comparison to natural gases

- Once stored in the correct manner, this recycled gas is able to replace propane and natural gas

- This recycled gas is also used as a form of energy inside gas burners

- The gas is also used by the recycling system in the pyrolysis of waste tires

The gas that is generated inside this system makes up 5 to 7% of the total weight of the recycled tires. For example, if a facility is recycling 9 tons of waste tires every day, they are able to generate between 1400 and 1500m of gas every day which offers a significant energy potential for a number of different uses.