If you live in a country where a great deal of biomass waste material is available, you can set up a great business by investing in a charcoal making machine. Charcoal is in great demand for residential use as well as for industrial use as it is a highly efficient fuel and is widely used in daily life. Another advantage of converting different kinds of waste such as coconut shell, rice hull and other such things into charcoal is that it also helps in reducing wastage by converting it into useful resources.

While there are a number of companies offering such machines, not all the machines available in the market are of the highest quality. Therefore, it is important for you to carefully consider different factors in order to choose the right machine for making charcoal.

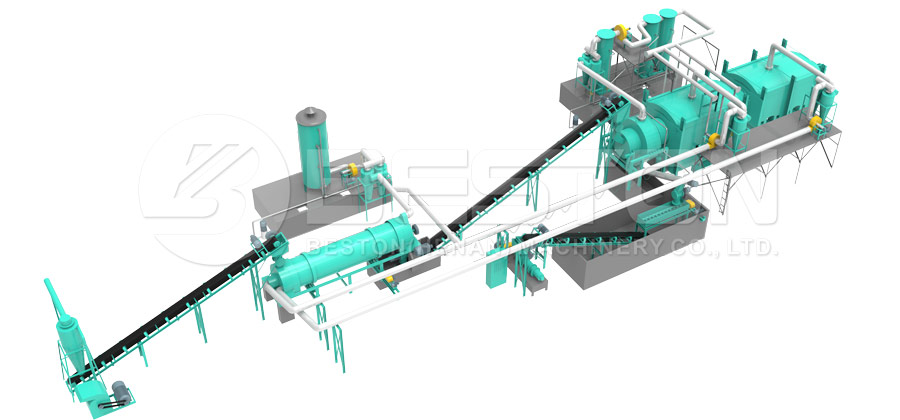

Design

One of the most important factors you need to look at is the design of the machine. Some of the machines available in the market are not designed to be as efficient as possible whereas there are models that are extremely efficient. Efficiency means the ratio of final product to the raw materials. Click here to know more: https://bestonpyrolysisplant.com/.

For instance, some machines are capable of converting up to 35% of the raw materials into charcoal whereas other machines can convert only up to 25% of the raw materials into charcoal. The best way to get the efficiency of the machine is to carefully check the specifications mentioned on the website on the manufacturer. You should also ask for reviews and testimonials from some of their past clients.

Pollution

The charcoal production process leads to production of various gases and other contaminants. If these are released outdoors, it may lead to pollution and that may attract fines depending on the pollution standards in your country. Therefore, it is important for you to make sure that the machine you are planning to buy is designed to cause minimal pollution. It should have sufficient filters and coolers in order to get rid of the pollutants in a safe manner.

Safety

Charcoal is produced through a process known as pyrolysis process. This process involves extremely high pressure and therefore, safety is of paramount importance. Safety depends on quality of the materials used for making machine as well as various safety measures to ensure that the coconut charcoal making machine and operators are always safe. There should be various sensors such as a pressure gauges, thermometers and other such gadgets to help operators operate the machine in a safe and sound manner.

Price

As far as the price is concerned, it is important that you do not pay attention only to the price but also to the reputation of the company. You will definitely find companies offering these machines at a cheaper rate as compared to the price quoted by some of the more reputable companies but keep in mind that lower price has its own cost. Usually, it means lower quality materials and poor customer service.

Customer Service

This machine has a few moving components that will wear down with time. Therefore, it is important that affordable spare parts are easily available in order to keep the machine running. Also, the company engineers should provide the necessary training to run the machine at optimum efficiency. See this blog: http://site-1190912-2242-9286.strikingly.com.

Conclusion

Overall, there are some of the important parameters you need to take into account in order to get the best value for your money when buying a charcoal making machine.