The global accumulation of discarded tyres presents one of the most enduring challenges in solid waste management. With millions of units disposed of annually, traditional landfilling and open burning have proven unsustainable, both environmentally and spatially. Tyre pyrolysis offers a technologically advanced and ecologically sound alternative by converting waste rubber into usable resources such as oil, gas, carbon black, and steel. Through the integration of advanced pyrolysis machinery, this process not only mitigates landfill pressure but also contributes to energy recovery and material circularity.

Transformation of Waste into Resource

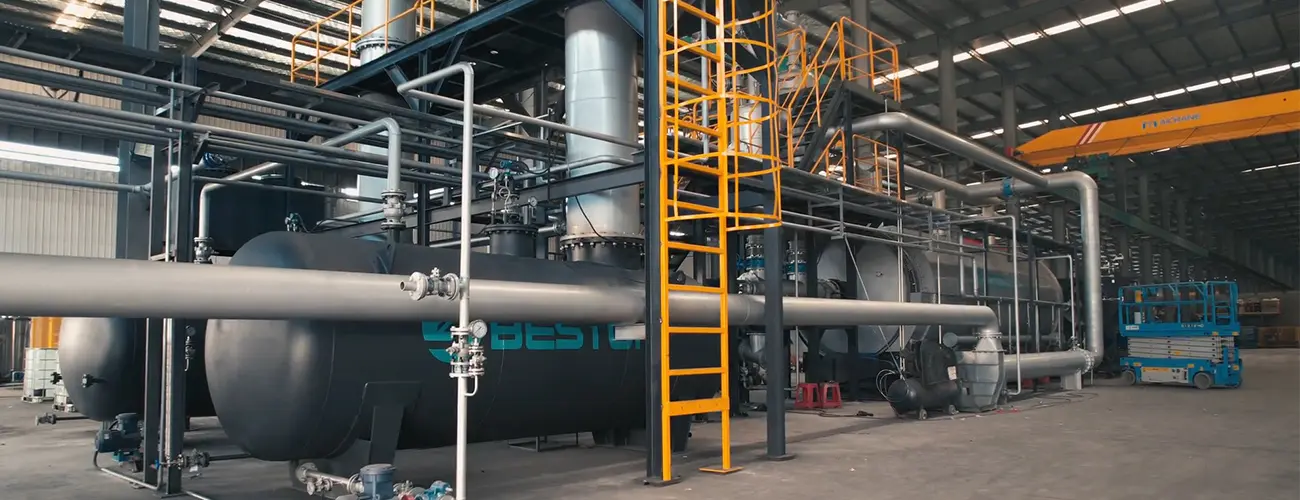

A tire pyrolysis plant operates by thermally decomposing shredded tyres in an oxygen-free environment, transforming complex hydrocarbons into valuable secondary raw materials. The resultant pyrolysis oil serves as a viable fuel substitute for industrial boilers and generators, while the non-condensable gases are recirculated to sustain reactor heating. The solid byproduct, rich in carbon content, can be refined into recovered carbon black for use in rubber manufacturing or as a reinforcing additive in construction materials. This closed-loop transformation exemplifies waste valorization—turning environmental liabilities into commercial assets.

Reducing the Strain on Landfills

Tyres are highly durable and non-biodegradable, occupying significant landfill space for centuries. Their hollow structure traps air, causing buoyancy that can damage landfill linings and complicate compaction. By diverting end-of-life tyres to pyrolysis facilities, municipalities can drastically reduce waste volume and extend the operational lifespan of existing landfills. Moreover, the adoption of large-scale tyre to oil plant systems ensures that waste rubber is continuously processed rather than stockpiled, preventing long-term accumulation and associated fire hazards.

Environmental and Energy Advantages

The environmental advantages of tyre pyrolysis extend beyond waste reduction. The process prevents harmful leachate formation and methane emissions that occur during tyre decomposition in landfills. A fully automatic tyre pyrolysis plant operates with high thermal efficiency, employing gas recycling and emission purification systems to ensure minimal environmental discharge. The recovered oil and gas substitute for fossil-derived fuels, lowering carbon intensity across industrial applications. By offsetting crude oil demand and reducing uncontrolled waste disposal, pyrolysis reinforces the transition toward a low-carbon, resource-efficient economy.

Economic and Infrastructure Integration

Pyrolysis technology aligns with modern waste management frameworks that emphasize decentralized processing and local energy generation. Establishing mid-sized facilities near urban waste sources reduces transportation costs and enhances logistical efficiency. The modular design of advanced pyrolysis machinery allows scalable operation—ranging from regional recycling centers to fully integrated industrial plants. These systems create employment opportunities, stimulate regional economic development, and reduce municipal expenditure on waste handling and landfill expansion.

Advancing Toward Circular Waste Systems

As regulatory policies tighten and sustainability goals evolve, tyre pyrolysis is poised to play a central role in future waste-to-energy strategies. Continuous improvements in reactor design, automation, and emission control enhance both economic feasibility and environmental performance. By bridging the gap between waste reduction and energy recovery, the tire pyrolysis plant represents a cornerstone technology in the pursuit of landfill-free, circular waste ecosystems—transforming end-of-life tyres into enduring environmental and industrial value.