If you are planning to set up a pyrolysis plant, you must be wondering whether it is still profitable to invest in. The biggest problem with such questions is that not every business is going to be successful or profitable in the long run. What you need to do before you put your money in the business is to know more about the business, for example, where to find the best quality pyrolysis machine for sale, how to lower the cost, etc.

As far as pyrolysis plants are concerned, there is a huge demand for such businesses as these are environmentally friendly and get rid of materials that can potentially cause a lot of harm to the environment such as waste tires. Therefore, there is absolutely nothing wrong with the business of pyrolysis but not every pyrolysis plant business is going to be successful. Here is what you need to do in order to ensure that your pyrolysis plant is profitable and successful in the long run.

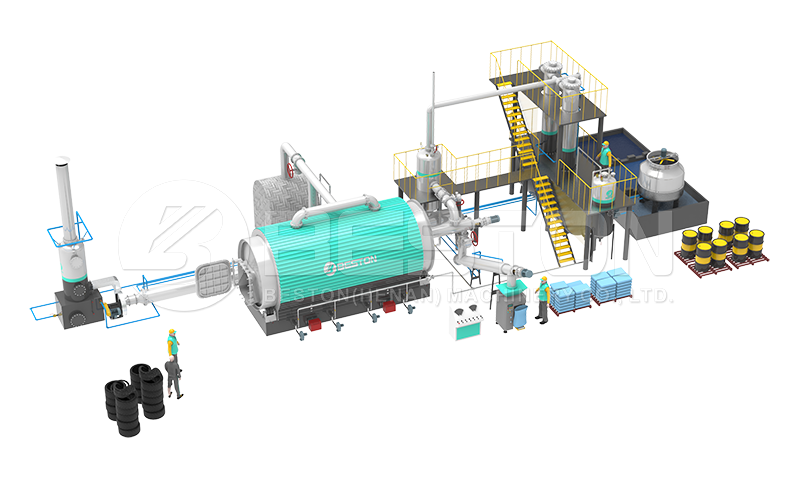

This is a technology-driven business. The technology you use is going to have a huge impact on the profitability of your business. Not every pyrolysis machine available in the market is the same. In the initial days, pyrolysis plants used to be highly inefficient in terms of power consumption and output. Thanks to many innovations over the decades, the modern pyrolysis plants manufactured by some of the leading companies in this industry are highly efficient and also lower the cost of pyrolysis plant. These plants make use of all the heat generated in the pyrolysis process to be used as a power source and in addition, these also come equipped with various components to ensure that no pollutants get released into the environment during the pyrolysis process.

Therefore, the first thing you need to ensure in order to set up a profitable business is the quality of the machine. You can’t compromise on the quality of the machine. If you compromise on the quality, you are going to struggle with the profitability of your business. Lower quality machines might come cheaper but will cost you a lot more money on repairs and maintenance.

Also, these machines tend to break down more frequently which means you will have longer downtime as compared to a high-quality machine. There other major differences between a lower quality pyrolysis plant and a high-quality one are power consumption. The modern high-quality pyrolysis unit is almost self-sufficient to reduce power consumption. Taking tire recycling plant for example, if you want to know the profit well, you can check the link here: https://bestonasia.com/tire-recycling-business-profit/.

In addition to the efficiency of the pyrolysis machine, another important thing that is going to have a huge impact on your business is the number of workers required for the continuous operation of the plant. There are 3 types of plans such as a batch pyrolysis plant, semi-continuous, and continuous plants. In a batch plant, the pyrolysis process takes place in batches whereas in a continuous plant, the operation is ongoing which means you never really shut down the plant completely and it keeps producing the profitable end products. However, you should invest in a continuous operation plant only if you’re able to find the demand for the end products produced as a result of the pyrolysis process.

Overall, not every pyrolysis plant is going to be successful and profitable in the long run. Therefore, you need to come up with a detailed pyrolysis plant project report to set up a strong foundation for a profitable business. Focus on quality of the machinery, level of automation as well as the design in order to set up a business which is likely to be successful and profitable in me long run.