You can find waste tyre pyrolysis plants in many countries all around the world. These plants are often set up to deal with mounting tyre waste in cities generated from more and more people now using cars as their main form of transportation. However, as well as helping to deal with environmental problems, a fully automatic waste tyre pyrolysis plant Indonesia, for example, can also generate lots of profit for the operates. This is because the output materials, which are fuel oil, black carbon, combustible gas, and steel wire, are in high demand in the international industrial marketplace.

Pyrolysis oil is the main end product from waste tyre recycling pyrolysis machines. In its raw state, the oil can be used as fuel for many types of industrial machinery, however, it can also be turned into diesel and gasoline through refinement processes. Oil and diesel are more marketable, so many recycle waste tyre facilities have refinement equipment onsite. The steel wire output by tyre-to-fuel pyrolysis machines is typically sold directly to steel refineries, where it is turned into various metal products. The carbon black that is output by said machines can be turned into powder using a grinding machine. The powder is a common colorant in the rubber, pharmaceutical and plastic industries. Visit this web – Beston Group Pyrolysis to learn more about final products.

As you probably already imagine, there are lots of different models of waste tyre pyrolysis machines available and choosing the right one to set up a profitable tyre pyrolysis equipment is important. You need to choose a reputable manufacturer and vendor. The best machines have excellent safety ratings and high-efficiency specifications. Many of the best suppliers are located in Indonesia, China, and India. Suppliers in those countries manufacture some of the most durable, high-capacity machines in the industry, yet perhaps surprisingly, prices remain competitive. Furthermore, the after-sales services offered by many of those suppliers is second to none. A team of expert engineers can be arranged to visit a buyer’s facility to assemble and commission new pyrolysis plant machinery.

Advantages Of Continuous Tyre Pyrolysis Plant Indonesia

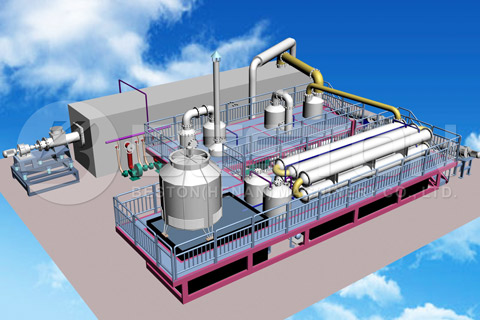

In sharp contrast to a batch processing machine, a continuous tyre pyrolysis plant Indonesia is designed to operate 24/7. The reactor does not require cooling between different batches, and waste tyres can be auto-fed into the reactor on a non-stop basis. Of course, it’s possible that a semi-continuous plant or a batch Tyre Pyrolysis machine might be a better match for the processing capacity needs of your business and your budget. The best suppliers can provide you with the expert advice you need to choose the best recycling plant equipment for your facility.

One of the most talked about manufacturers in the waste tyre pyrolysis machine is Beston. The manufacturer produces a wide range of different models designed to suit the needs of facilities with different processing capacity requirement. The BLL-20 model, for example, has an ultra high production capacity of 24 tons per day. It is a highly efficient plant with automatic and continuous feed and discharge configurations.