The process of converting wood into charcoal is a complex one, with various factors influencing the yield and quality of the final product. Different types of wood can have a significant impact on how effectively the charcoal is produced. The pyrolysis method, which involves heating wood in the absence of oxygen, is used in a wood charcoal machine to create charcoal from organic material. This article examines the effects of wood type on the charcoal making process, focusing on factors such as composition, heating characteristics, and final product quality.

The Basics of Charcoal Production

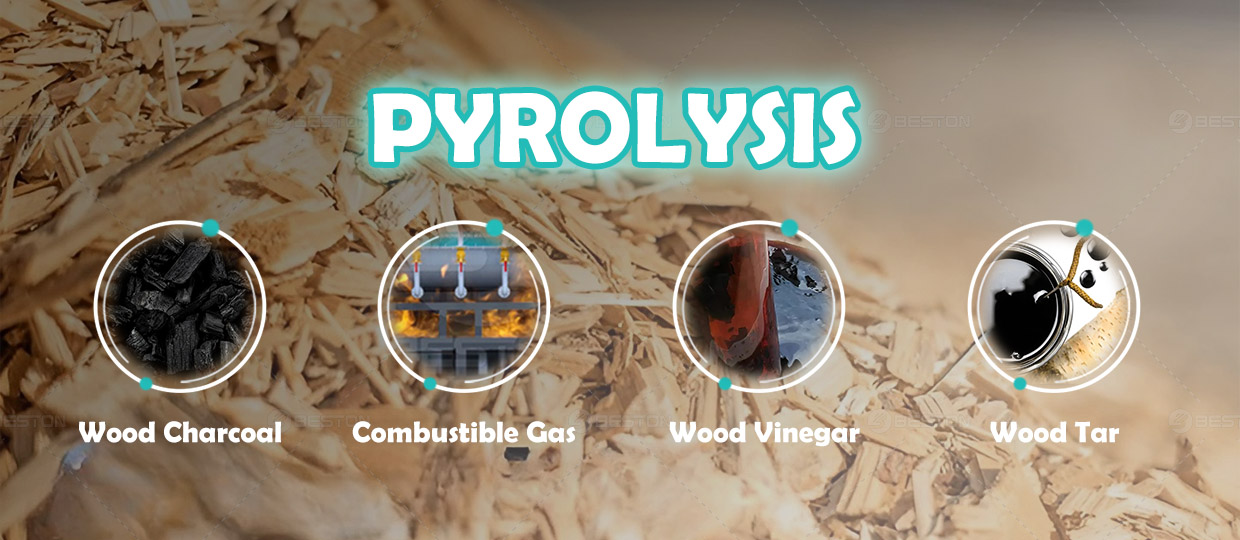

To understand how wood type affects charcoal production, it’s essential to first examine how charcoal is made from wood. The process begins with the wood being subjected to high temperatures in a wood charcoal machine, which heats the wood in the absence of oxygen. This pyrolysis process breaks down the cellulose, hemicellulose, and lignin in the wood, resulting in the release of volatile gases and leaving behind solid carbon-rich material—charcoal.

The efficiency of this process, as well as the characteristics of the resulting charcoal, depend heavily on the type of wood being used. Hardwoods, softwoods, and even certain types of agricultural residues can all yield different results, influencing the energy output, burn time, and quality of the charcoal.

Composition of Different Wood Types

The primary factor that determines how wood behaves during the pyrolysis process is its chemical composition. Different wood types have varying proportions of cellulose, lignin, and other organic compounds, which affect how they decompose when heated.

- Hardwoods (such as oak, hickory, and maple) tend to have a higher lignin content compared to softwoods. Lignin is a complex polymer that, when burned in wood pyrolysis plant, contributes to the durability and density of the charcoal. As a result, hardwoods typically produce a denser, more compact charcoal with a longer burn time.

- Softwoods (such as pine, spruce, and fir) have a higher proportion of cellulose and a lower lignin content. This means that softwoods often produce lighter, less dense charcoal with a shorter burn time. However, they also tend to ignite more easily and burn at a higher temperature, making them ideal for certain types of cooking or industrial applications.

- Fruitwoods (like apple and cherry) are often prized for their aromatic qualities, which add flavor when used in grilling or smoking. These woods may produce charcoal with a distinct aroma, though the burn time and overall efficiency may vary depending on the specific composition.

Heat Transfer and Pyrolysis

The heat transfer characteristics of different wood types can also influence the charcoal making process. The density and moisture content of the wood play crucial roles in determining how efficiently heat is absorbed and retained in sawdust charcoal making machine.

- High-density woods, like oak or beech, have more tightly packed fibers, which can absorb heat more slowly. This slow heat absorption can lead to a more controlled pyrolysis process, potentially resulting in a higher yield of charcoal per unit of wood used. The slower process can also help preserve the integrity of the carbon content, resulting in higher-quality charcoal.

- Low-density woods, such as pine or poplar, heat up more quickly and may undergo pyrolysis at a faster rate. While this can result in quicker production times, it may also lead to a lower-quality charcoal with less carbon content and a higher proportion of ash. However, low-density woods can be advantageous for certain applications, such as in producing charcoal for quick-use purposes.

Moisture Content and Its Impact

The moisture content in wood can significantly affect the pyrolysis process. Wood with a high moisture content requires additional energy to evaporate the water before pyrolysis can begin. This not only prolongs the process but can also result in a lower yield of charcoal. It’s generally more efficient to use well-dried wood in a wood to charcoal machine, as this ensures a more effective conversion to charcoal.

- Hardwoods tend to have lower moisture content compared to softwoods, meaning they require less energy to begin the pyrolysis process and typically produce higher-quality charcoal.

- Softwoods, with their higher moisture content, may produce charcoal that is less durable and more prone to crumbling, as the additional water in the wood can inhibit the carbonization process.

Conclusion

The type of wood used in a wood charcoal machine plays a critical role in determining the efficiency and quality of the charcoal produced. Hardwoods generally yield more durable, higher-quality charcoal with a longer burn time, making them ideal for industrial and long-duration applications. Softwoods, though less dense and producing less durable charcoal, offer quicker ignition and higher burn temperatures, making them more suitable for applications requiring rapid heat.