The invention of the egg tray machine has been a beneficial addition to the manufacturing industry. The need to create sustainable products by using safer means of production increases the demand for this machine. The initial version was a standard model suitable for primary production. Manufacturers now leave room for customization hence the availability of different designs of the device. Before making settlements, it is imperative for an in-depth evaluation of your business. Understanding your needs will guide you to choose an appropriate egg tray machine model. All of them assume a similar production process but have varying functionality levels.

Fully Automatic.

The first design is the fully automatic egg tray machine. It is the number one and the best in the category. The device can independently produce a large number of egg trays without the need for manual labor. The only input required from the operator is loading the raw materials in the mixing location. However, a water source with a metering system is available to monitor only the required amounts that get used. The average production for this design is 12000 pieces of egg trays within a given hour. The number makes it suitable for large-scale locations with a huge demand for the product. The rate of production is high hence lower energy consumption. Although investors have to pay more during purchases, they have an assurance of smooth and affordable operations throughout. Also, it uses a metal drying line at the third stage of production. The provision ensures it can sufficiently dry a large number of products within a shorter period. Investing in the setup will cost more, but the returns are worth it. You save on energy, labor and uphold your business reputation. See egg carton making machine here.

Semi-Automatic Model.

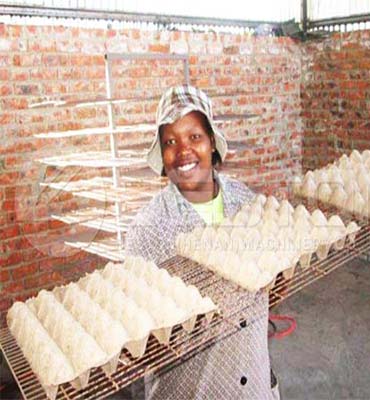

The second version of the semi automatic egg tray machine for sale is an option with features more or less than the first machine. Its purchasing price is far much lower but at the expense of a few concerns since its average production rate is a maximum of 8000 egg trays per hour. The quantity is still huge but ideal for markets with average demand. The machine requires some human effort to expedite some parts of the manufacturing process. Its drying line features a brick system. The structure is quite costly to set up but works efficiently to beat downtime. The machine works reliably only in the appropriate locations.

Manual Egg Machine.

The final design is the manual egg tray machine. It relies on human effort to undertake its tasks. Such conditions achieve a minimal amount of egg trays compared to what the above can deliver. The model can deliver an output of 4000 pieces for the same period. Investors spend way less during purchasing. However, they incur huge bills providing for diesel or any other source of power and labor costs. The functionality means it can only work in a location with a small need for the relevant products. More information on https://bestoncompany.com/egg-tray-making-machine/btf1-3-1000pcs/ here.

As seen above, each of the machines works towards delivering egg trays but has varying capabilities. Placement is critical if you want to benefit from optimal performance.