The demand for ecologically sustainable products has led to an increase in the need for pulp molding machines. Currently, there are numerous versions in the market suitable for varying work setups. One notable aspect of this paper pulp molding machine is its purchasing price. There is a wide price disparity causing a stir among buyers. Every investor in this industry needs to understand the factors affecting this aspect before making a sound decision. They might seem insignificant but give a deeper insight into the type and functionality levels of the machine. Below are the common factors affecting the pulp molding machine price.

Functionality Levels

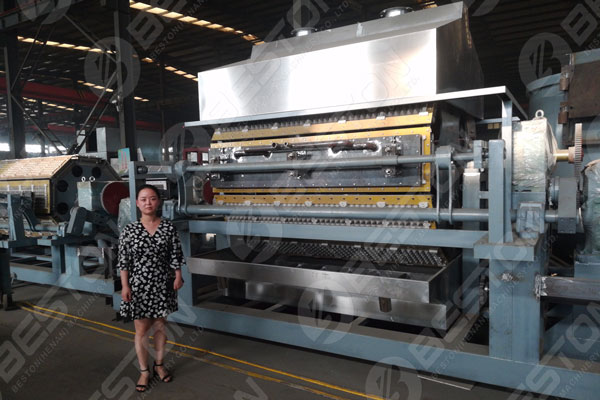

One misconception in the industry is that a more significant device would perform better than a smaller model. Well, it is the configurations of a machine that determine how effective it will serve you. Hence, manufacturers employ different designs, such as manual, semi, and automatic egg tray machines. For instance, a device capable of meeting a higher demand within a shorter time will cost you more than a slower type. Also, a machine that employs plastic molds will cost more than one using metal molds. If you opt for a traditional pulping system, you save some money than using more advanced integrated features. However, all these features are vital as they define the kind of experience you get upon investing. You may save some money upfront but incur more costs in the long run. A budget is vital to guide you along this process.

Drying System

Drying of the egg trays is a crucial part of the formation. It determines the quality of the end product, whether it will serve for an extended period or get destroyed along the way. There are three types of drying systems employed in this aspect. They hugely affect the overall pulp molding machine price since their costs vary. The first type is sun drying. It is almost free, but you have to invest further in an egg tray drying machine. The method is slow and comes with lots of inconveniences, thus suitable for small-scale investors. The second version is the brick drying line. Its price is much higher since you have to invest a lot in building the structures. However, its functions are much better since it can dry many egg trays within a short period. The last version is the metal drying design. It is the most expensive among them all. The design features conveyor belts that move around the trays for the even distribution of heat. It is energy efficient as it can completely dry the trays using the retained heat in the system. The model is ideal for large-scale production organizations. Although each option works towards a similar goal, it is imperative to place them for better performance optimally. Know more about the drying system: https://pulpmouldingmachines.com/egg-tray-making-machine/dryer/.

The other factors affecting the egg tray production machine include labor costs incurred during production such as electricity, shipping, a variety of raw materials, and government tariffs. The seller would sum all and arrive at a fair selling price for the pulp molding machine. The factors above are all essential as they give you a better insight into the ideal device.